The content of the article:

- A bit of history

- Types of torsion suspensions

- Description of the torsion

- Principle of operation

- Advantages and disadvantages

- Scheme

- Price

Torsion bar - refers to the class of independent suspensions, which is based on a torsion bar. It is like the main elastic element, which is applied on a level with a pneumatic bellows or a spring. This type of suspension provides the car with a number of advantages: smooth running, compactness, simplicity of design. But there are also significant disadvantages, such a design has the worst handling and rolls of the machine itself. As a result, this species is not often found on modern cars.

The history of the appearance of the torsion bar suspension

The first mention of the appearance of the torsion bar suspension dates back to the 1930s of the last century. Then it was installed on French Citroen cars. Beginning in the 1940s, the mechanism migrated to Porsche racing cars. In the future, the design began to be used on ZiL, Chrysler and Renault 16 cars.

Then the main plus was in the smoothness of the ride, simplicity of design, and of course inexpensive parts in case of repair or production. Progress was not long in coming, and over time, due to poor handling, the entire mechanism faded into the background, giving way to a multi-link or MacPherson suspension. Nevertheless, at Chrysler, this suspension lived the longest, due to its simple design, it was installed on cars from 1957 to 1989 inclusive. The very word torsion is translated as twisting, respectively, this is the basis of the work of the part.

What are the torsion bar suspensions of the car

Despite the fact that the torsion bar suspension showed itself only 50% from the best side, many applications were found for it on different cars. Accordingly, there are several types of refinement of the mechanism. As a rule, there are three main variations:

- front torsion bar on wishbones;

- rear suspension with transverse torsion bars;

- semi-independent rear torsion bar suspension (beam).

Each of the listed types differs not only in structure, but also in characteristics and design. The front torsion bar suspension includes:

- longitudinal torsion bar working on the twisting principle;

- lower and upper arm;

- shock absorber;

- anti-roll bar.

Such a set of parts makes the whole mechanism compact, which makes it possible to modify the wheel drives, install tires of a larger diameter. It was these moments that served as a plus for the production of frame SUVs, which should combine softness, smoothness and increased cross-country ability. As an example, such a suspension can be found on Toyota Land Cruiser 100 or Toyota Hilux Surf SUVs.

The second type is the rear suspension with transverse torsion bars. In such a mechanism, the main torsion bars are located transversely. This is exactly how the system was arranged in the legendary French car Renault 16, produced in the 90s of the twentieth century. At the front, the car received a suspension with a longitudinal arrangement of torsion bars, but at the rear - with a transverse arrangement. The popularity of the model was due to the free space in the cabin, in particular the luggage compartment. The use of this design significantly freed up space in the trunk, but there were also disadvantages.

Was very interesting design feature of such cars... To the extent that one torsion bar is located behind the other, this led to a difference in the wheelbase of the car. One wheel on one side was closer to the front by a few centimeters, the other wheel, on the contrary, was a few centimeters farther. It was difficult to see by eye, since there was practically no comparison from the side, but the car's handling was not the best, similarly, as was the stability on the track (especially at high speed). Today, such a suspension scheme is not used by auto manufacturers, to the extent of safety reasons.

The last option is a rear semi-independent torsion bar suspension. As a rule, it is of the correct U-shape, which has received an elastic rod inside. Due to this design, the wheels of one axle can move slightly from each other, which makes it possible to drive bumps more smoothly. In this way, the best vehicle stability and handling is achieved. As a rule, the suspension is used on the rear axle of most budget front-wheel drive cars. Inexpensive production, relatively cheap parts and good performance.

What is a torsion bar and how it works

Often, the principle of the structure of one of the above-mentioned types of suspension is different, respectively, and the details will differ from each other.

According to the device, a torsion bar is a metal rod or shaft, the main task of which is to work on twisting (only in one direction). If we consider it in a dissected form, then in shape it can be square or round, much less often in the form of plates, which consist of several layers.

For the system to work, one part of the torsion bar is rigidly attached to the suspension (support arm), due to the splined connection. The second part is fixed on the car frame or body, depending on the design. The engineers calculate the torsional resistance of the torsion bar in advance, thereby optimally designing it to support the weight of the car and a stable connection between the frame and the car body. This is the same principle used by engineers when designing anti-roll bars. The main characteristics to consider are thickness and length. It is they who play a role in the softness of the suspension and are able to withstand the necessary overloads; if these data are violated, breakage or bending may occur. To protect against rye and other damage, from the moment of production, the parts are covered with a special rubberized material, as well as an anti-corrosion agent.

The principle of operation of the torsion bar suspension

The principle of operation of a torsion bar suspension reminds many of the operation of a leaf spring, air or spring suspension. Above the described parts, it is clear that the torsion bar, the main part, acts as a spring. At the moment of operation, the force is transmitted to the torsion bar from the main, bearing lever.

Thus, the rod is twisted to the required or possible limit. At the moment when the load decreases, the bar returns to its original position. This aligns the position of the support arm.

Pros and cons of torsion bar suspension

As with any mechanism, the torsion bar suspension can surprise with both positive and negative aspects. To do this, consider them in the table:

| Pros and cons of torsion bar suspension | |

| pros | Minuses |

| Compact dimensions | Poor vehicle handling |

| Light weight of parts | Difficulty in the production of the torsion bars themselves |

| Smooth running | It is almost impossible to achieve good sound insulation |

| Good maintainability | You need to drive carefully and carefully. |

| Reliable and simple suspension design | The torsion bar has a tendency to pop |

| Inexpensive service | — |

| Self-adjustment of suspension stiffness (sometimes clearance) | — |

To fully appreciate the pros and cons of a torsion bar suspension, you can only travel on cars with different types of suspension. But if for some reason you have not previously encountered or were not interested in the device of the mechanism, then before buying a car, you should definitely drive at least a few kilometers in order to fully feel the pros and cons.

Car torsion bar suspension diagram

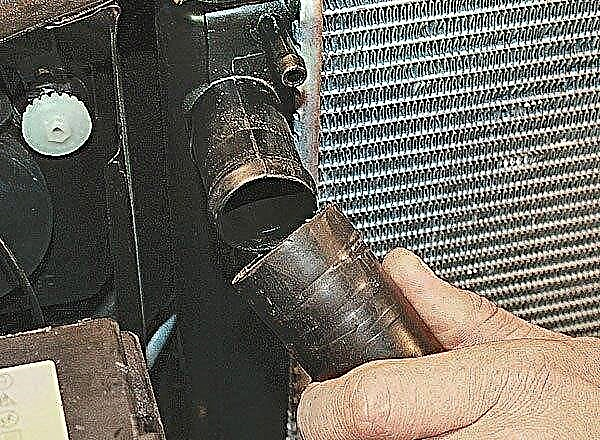

The photo shows a diagram of the front torsion bar suspension

- Lower arm;

- Shock absorber;

- Wheel drive;

- Upper arm;

- Spherical bearing;

- Torsion;

- Mounting frame;

- Wheel.

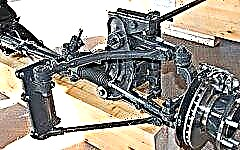

The photo shows a diagram of the rear torsion bar suspension.

- Shock absorber;

- Shock absorber spring;

- Torsion;

- Brake pad lining;

- Hub and brake disc;

- Fastening to the car frame;

- Torsion;

- Torsion bar mount;

- Lever arm.

Torsion bar suspension parts price

Finding a car with a torsion bar suspension today is quite easy, most often it is installed as a rear axle for inexpensive front-wheel drive cars. To understand how much the repair parts cost, consider the Renault Kangoo as an example.

| Prices for torsion bar suspension parts Renault Kangoo 2008 | |

| Name | Price from, rub. ($) |

| Torsion | 6501 ($87) |

| Torsion bar holder | 320 ($5) |

| Silentblock | 320 ($5) |

| Rear spring | 3810 ($51) |

Despite the very simple design, the parts for the torsion bar suspension of the car are not that cheap. Accordingly, maintenance of the suspension is not the cheapest, especially when one of the torsion bars bursts.

Due to its dimensions, the mechanism takes up little space, and according to the type of construction, some experts attribute it between dependent and independent suspension. Therefore, in some sources it is also called a semi-independent suspension. From the pros, you can note the smoothness and compactness, with the minuses, poor controllability and the possibility of failure of the torsion itself.