The braking system of a car consists of many elements and assemblies, the most important of which is the brake master cylinder. Its scheme and principle of operation are described here.

The content of the article:

- Brake cylinder diagram

- Device and principle of operation

The braking system of a car consists of many elements and assemblies, the most important of which is the master brake cylinder. It is needed in order to convert into hydraulic pressure, the forces that are applied in the brake system to the brake pedal.

The main two-piece brake cylinder is usually installed on modern cars. The brakes of the left rear wheel and the right front wheel, in front-wheel drive vehicles, are united by one of the circuits, and the right rear wheel and the left front wheel are united by the second. The braking system in rear-wheel drive cars is built on a different principle. The second circuit serves the rear wheels, and the first circuit serves the front wheels.

The fastening of the main brake cylinder takes place on the vacuum brake booster, namely on its cover. A reservoir with two sections, in which there is a certain supply of brake fluid, is connected to bypass and compensation holes, sections of the master cylinder, and is located above the cylinder itself. It is needed in order to replenish its supply in the event of evaporation or leakage of brake fluid. For the convenience of measuring the level of such a liquid, there are marks for control (usually "MIN" and "MAX") on the walls of the tank, which are transparent, and there is also a sensor in the tank that shows the level of the brake fluid. If the level drops below that which is installed on the dashboard, then a warning lamp on the dashboard makes itself felt.

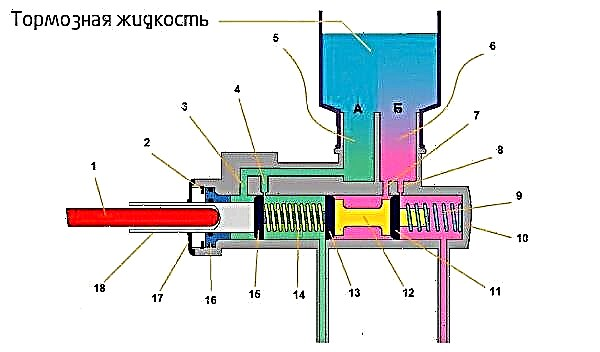

Car brake master cylinder diagram

- the rod of the vacuum brake booster;

- retaining ring;

- bypass opening of the primary circuit;

- compensation hole of the primary circuit;

- the first section of the tank;

- second section of the tank;

- bypass hole of the second circuit;

- compensation hole of the second circuit;

- return spring of the second piston;

- main cylinder body;

- cuff;

- second piston;

- cuff;

- return spring of the first piston;

- cuff;

- outer cuff;

- anther;

- first piston.

In the body of such a cylinder, two pistons (12 and 18) are placed, which are located one after the other. The second piston is freely installed, while the first piston interacts with the brake booster rod, which abuts against it. Rubber seals function as piston seals, which, as we already know, are located in the cylinder body. Return springs (2 pieces "9, 14"), hold and return the pistons.

How the main brake cylinder works and how it works

While braking occurs, the first piston is pushed by the brake booster rod. When the piston moves along the cylinder, it closes the hole, which is compensating, because of this, the pressure in the first circuit also increases, as a result of which the second circuit moves, which also leads to an increase in pressure in it. The brake fluid, through the bypass hole, fills the voids that arise when the pistons move. The return spring controls the movement of both pistons, the actuation of the brakes is due to the maximum pressure that is created in the circuits.

The pistons return to their original position when the end of braking occurs. The pressure in the circuit is equalized with atmospheric pressure, this occurs during the passage of the piston through the expansion hole. The brake fluid that fills the cavities prevents the discharge that could occur in the working circuits when the brake pedal is suddenly released. When the piston moves, fluid is returned through the bypass hole back into the reservoir.

Regardless of the possible leakage of brake fluid in one circuit, the second circuit will not stop working. If such a leak occurs in the first circuit, then it makes a movement that occurs in the cylinder, and comes into contact with the second piston, and it, in turn, ensures the operation, in the second circuit of the braking mechanisms, by its movement.

When a leak occurs in the second circuit, the brake cylinder works differently, namely, the second "pusher" begins to move with the help of the first, its movements are unimpeded, and only limited by resting on the end face of the cylinder body. Due to the increase in pressure in the primary circuit, the vehicle is braked. Braking is quite effective despite the increased brake pedal travel that occurs when fluid leaks. If there are obvious problems with the brake system, then you need to start inspecting the brake system and, if necessary, replace this cylinder. For more details, read the article: "How to change the master brake cylinder."