The content of the article:

- Alternator Belt Diagnostics

- Belt whistle

- Insufficient tension

- Use of auto chemistry

- Alternator belt - features of choice

The alternator belt is a thin elastic ring needed to transfer torque from the crankshaft to the alternator. As a result, the vehicle receives electrical energy that powers the vehicle's systems. In order for the belt to operate for a long time, it is made of special rubber of different grades, applied to several layers of nylon cord.

Alternator Belt Diagnostics

There can be several reasons for the failure of the generator, ranging from the simplest - a high load on the unit, ending with the operation of the machine in conditions of high humidity, with intense temperature changes. To identify problems with the alternator belt, it is necessary to carry out diagnostics in a timely manner. This is a visual inspection.

The wear of the elastic transmitter will be determined by the driver without experience. Damage, delamination of the structure, protruding cords, uneven wear of the contact surface, torn parts - all these are evidence of the need to replace the component.

Belt whistle

When the car engine is started, a whistle appears, which indicates the incorrect operation of the generator. Most often, the problem lies directly in the damage to the belt structure, poor-quality materials used for production, or accumulated dirt on its surface. It is also worth inspecting the bearings, pulley, and roller belt tensioning mechanism.

When inspecting spare parts, you should pay attention to the presence of cracks on the surface of the belt, as well as to the degree of its tension. In most cases, it is the lack of tension that causes an unpleasant whistle sound. The presence of dirt, a thick layer of dust, various liquids, lubricants can also provoke an annoying sound.

The problem is eliminated by purchasing a new original part, which guarantees comfortable operation of the car for a certain period of time. But if the reason was contamination, then it is best to independently clean the belt from fluid or any grease.

Some car owners note the appearance of a whistle in the winter. When the rubber becomes hard at subzero temperatures, the belt loses its elasticity. As the engine components warm up, the sound begins to subside. Cars where, in addition to a belt drive, there is a tension roller, also emit an annoying squeak when the bearings are worn.

After visual inspection and confirmation of the problem with the alternator belt, the mechanical part should be checked. It is worth starting with a tensioner, which on each vehicle has individual parameters and is structurally different. The most common option is a brace that adjusts the tension level. If a problem is found, then you can start replacing the belt with a new one.

Insufficient belt tension

Weak tension reduces the efficiency of the generating device by several times, due to which the electric current of the required strength is not generated. Insufficient tension leads to rapid failure or rupture of the alternator belt. Therefore, you need to focus on the data declared by the machine manufacturer when adjusting the tension, or use the recommendations of experienced craftsmen, so as not to pay twice for the time and materials spent.

If a tensioning bracket is installed in the car, then the cause of the wear of the elastic band may be the failure of the roller. To make sure that the diagnosis is correct, you will have to completely remove the belt, examining it for external inconsistencies, damage, and the presence of backlash. If this is the case, the unit must be replaced. It is also recommended to check the pulleys for distortion, bearings in relation to the axis of motion.

Use of auto chemistry

If the unusual sound of a belt in a car does not have a constant character and duration, and an external examination did not reveal anything, then the reason lies in poor-quality material. In this case for prevention, it is worth using special additives - conditioner-tensioners in the form of spray cans. After processing the belt with these compounds, it becomes more mobile, elastic.

Alternator belt - features of choice

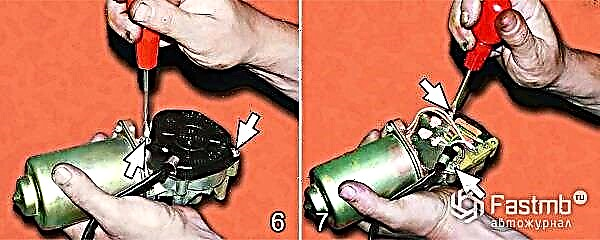

Belts are replaceable parts that cannot be restored and repaired. Therefore, in order to avoid unpleasant situations on the road, you need to monitor their condition. It is recommended that you carry a spare alternator belt in your car to replace in the event of a break. This will require the use of a screwdriver and physical force.

When choosing a alternator belt, consider:

- length;

- profile (height);

- width;

- thickness.

These parameters are not standard, the exact values are indicated by the car manufacturer in the technical documentation. It is important that the alternator belt matches them, otherwise the efficiency of the unit will decrease, several systems of the car will be damaged, and the life of the spare part will be reduced. The intensity of the loads also plays an important role here. Frequent trips will accelerate belt wear.

The technical information for the belt is encrypted in the catalog number. This is a combination of letters and numbers, which can be decoded without problems using online catalogs and special programs.

Another important point is the manufacturer. It is recommended to install original belts. The word "original" means full compliance with the manufacturer's recommendations for geometrical, technical and technological parameters. Spare parts that are suitable only in size are called analogs. They are divided into high quality and low quality. The determining factor here is the materials used for production. Saving in this case turns into even greater costs, so buying an original alternator belt would be a rational solution. This will save you from problems with the car's power supply for a long time.